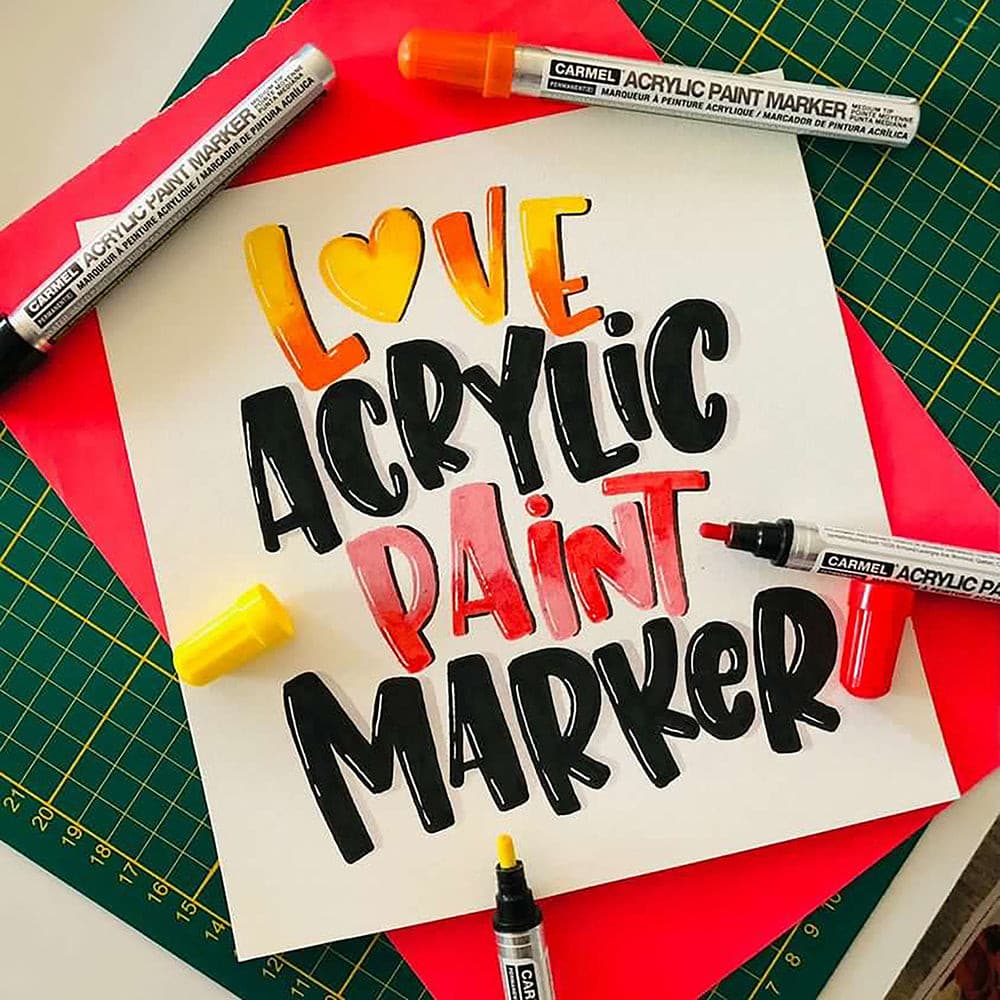

Scannable lumber markers are specialized marking tools used in the lumber grading process. They come in two forms, either as scannable lumber crayons or sticks of scannable lumber chalk. Before we get into how they are used, let’s take a moment to learn more about lumber and how it’s graded

When most people think of wood and lumber, they probably don’t give much thought as to where it came from. It’s enough to think that if something seems to be made of wood, that wood was probably bought at a hardware store, and ultimately came from a tree. While that’s true, there are many more steps involved for a tree to end up as lumber sold in a store.

One of the most important parts of a piece of wood’s journey from a tree to its end use is the process of grading. Because not every piece of lumber is created equal, this grading process determines what a given plank of wood can be used for.

For example, wood that’s meant to act as a support in the skeleton of a home might be different than wood that’s used to make a table, chair, or floor. The same goes for wood that’s used to make decks, or trim around doors and windows, and so on. Some applications focus more on the structural integrity of the wood, while others focus more on its appearance and resistance to daily wear and tear.

The job of lumber grading specialists is to evaluate every piece of lumber, assign it a grade, and ensure it’s properly sorted depending on its qualities. That’s how we can ensure that we’re using the right piece of wood for the right job.

One of the tools they use in grading lumber is the scannable lumber crayon or chalk (sometimes referred to as grade markers). These marking tools are used to mark planks which are then read by specialized scanning machines that sort lumber.

Before we get into how that works, it’s important to ask the question: what makes a given piece of wood so different from another?

From the Tree to You

It all starts with the tree. When you look at a pile of lumber in a store, it probably looks fairly uniform. That’s because it came from a bunch of different trees and has been properly processed, graded and sorted. If you look at a tree, it’s anything but uniform in structure.

For simplicity’s sake, imagine a tree (say a large pine), and then divide it into three sections. There’s the bottom section of the trunk with no branches, then a middle section higher up with a few larger branches, and finally the top section with many smaller branches. When the tree is felled, loggers will strip it of its branches and generally cut the trunk into these three sections called logs.

As the logs are cut and processed into planks (such as 2 x 4’s), each section will yield planks with different characteristics. These will largely determine how the planks are graded and sorted.

One of the most important qualities that separates pieces of wood is the amount of knots present. These are the brown circular shapes that we are all familiar with. Think of these knots as the junctions where branches linked up with the trunk.

Planks of wood from the lower trunk will have little to none of these knots, while planks cut from further up the trunk will have more. Those with less knots are generally seen as more desirable pieces, both for aesthetic appearance and structural integrity.

Another quality is the strength of the wood, which is traditionally determined using a bend test. This is used to select pieces of wood that will bear support loads without flexing.

By the time lumber gets to the retailer, it has been carefully tested, graded and sorted for its intended use. It’s also usually been dried, trimmed and treated to enhance its properties such as moisture and pest resistance.

The Lumber Grading Process

Generally speaking, the word “lumber” refers to cut wood – for example, wood that has been shaped into planks or beams. There are a few key distinctions in lumber to note before we get into grading. The most common distinction is between hardwood and softwood lumber.

Hardwood is more durable but harder to harvest and shape. It comes from trees such as maple, oak, and walnut. It’s commonly reserved for quality furniture and flooring, as it looks nicer and resists wear and tear better than softwood.

Softwood comes from trees that grow more quickly such as pine, spruce and cedar. While it is “softer” than hardwood, it’s still the main type of wood used in construction, such as in your home’s walls. It’s ideally used in places that won’t come into regular contact with human activity – foot traffic, eating, cooking, etc.

Since softwood lumber is primarily used in construction, its planks are sometimes referred to as “dimension lumber.”

After a piece of lumber is analyzed, it’s given a grade. The grading systems vary from country to country, but they essentially all assign some standardized grade to a given piece of lumber based on a few key elements. Along with a few other characteristics, this grade is stamped on every single piece of wood before it reaches retailers or wholesalers.

In Canada, each plank of wood will have a special stamp on it which gives information about where it comes from and of what quality it is. In general, a lumber stamp will include:

- Grade

- Sizing (e.g. 2 x 4”)

- Species or species group (e.g. pine)

- Moisture content

- Grading agency

- Mill designation

The grade is divided into seven ranks each with their own name. For example, the highest quality grade is called First & Seconds (FAS) and the lowest is called 3A Common. A professional contractor should know which grade of wood to buy for a given job.

Where Do Scannable Lumber Crayons/Chalk Come In?

Lumber is graded in one of two ways: either by human inspection or by high-tech machines that can analyze the wood without even touching it – usually by x-ray. In most cases, there is some combination of human and machine activity that goes into this process. Scannable lumber crayons/chalk come into play when humans feed marked-up lumber planks into specialized scanning machines.

When a lumber grading specialist tests a piece of lumber for grading purposes, they will usually conduct a visual inspection of the knots present and a bend test to evaluate the piece’s strength and flexibility. Each and every piece of wood is carefully analyzed in this way to determine its grade.

In some cases, planks of wood are fed into specialized scanning machines after they have been tested by a specialist. Grading specialists use scannable lumber crayons or chalk markers to write information on the planks which they have evaluated. The machine will then scan and interpret the markings for inventory and sorting purposes.

Scannable grade marking crayons are wax-based while scannable lumber chalk markers are sticks of specialized chalk. They essentially perform the same task.

Both scannable lumber crayons and chalk are highly specialized in their application and were developed to be used in conjunction with specific lumber scanning machines such as those made by Lucidyne, Cypress, and Newnes/McGehee. They leave fluorescent, UV-scannable markings which are crucial to this type of lumber grading process.