As metal fabricators know, galvanizing is the process of is the process of applying a protective zinc coating to steel or iron, to prevent rusting. The most common method is hot-dip galvanizing, in which parts are submerged in a bath of molten zinc. This process is fairly simple compared to other methods of corrosion protection. However, before galvanizing any steel piece, the most crucial step is prepping the surface for its coating. In the majority of instances where coatings fail, it is due to incorrect or insufficient preparation of the surfaces beforehand. Getting the surface ready requires 3 main steps: degreasing, pickling and fluxing. It’s in the pickling bath, when any markings made on the steel with Galvanizer’s Paint Markers, are lifted away.

Unintentional Damage

Most directions for these protective-coating processes include details on surface preparation prior to application of the coating. As mentioned above, for galvanizing, the process is pretty straight-forward. However, one thing that is often neglected are the marking tools workers use to label their pieces. There are chemical reactions that occur when using the wrong ink or paint, and we must avoid unintentionally damaging the surface in this manner.

Materials which the Cleaning Chemicals Cannot Remove

There are some substances the cleaning chemicals used prior to galvanizing cannot remove, or have great difficulty removing. Among these we find oil-based paints and markers, and crayon markers and with the risk of reactivity (corrosion) with various ink or paint chemicals, fabrication of steel requires specialized tools. Thankfully, galvanizing-safe markers are available, and these dissolve in the cleaning baths used in the galvanizing process.

What are Carmel’s Galvanizer’s Paint Markers?

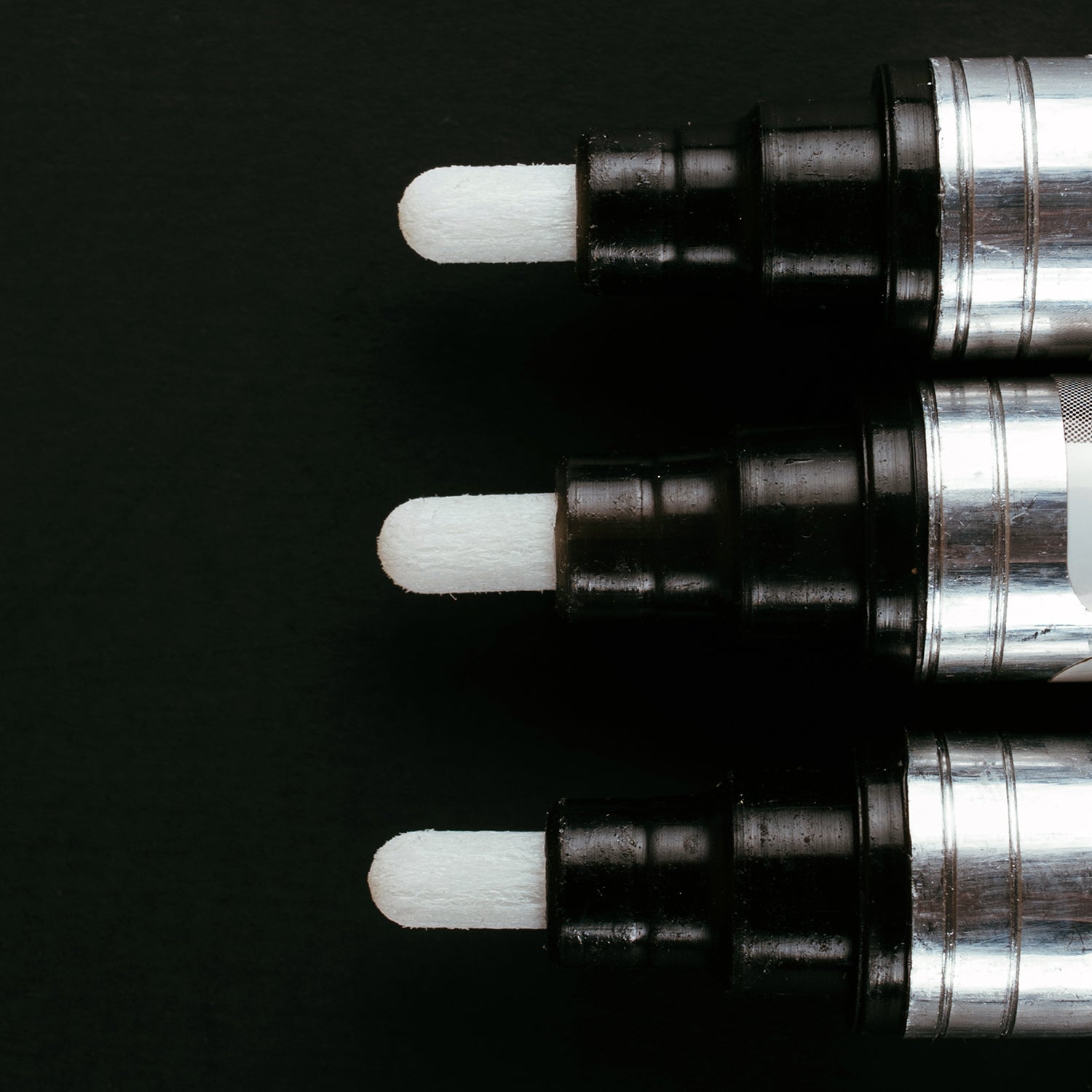

Our specialty-designed Galvanizer’s Paint Marker dispenses paint with little effort. They are specifically formulated for use prior to galvanization, are weather-resistant, and dry fast. Marker writes easily on any steel surface, whether rough, smooth, wet or oily. Marks won't rub off, peel, chip, or fade. However, they are completely removed in the pickling bath prior to galvanizing and leave a clean surface, thus never impeding on the zinc plating process, with no marks left on the finished product.

Paint markers for the galvanizing industry save time and effort because they come off during the cleaning process without lengthy sanding or grinding. If you're in Metal Fabrication or Plating, specify these markers to your Management/Foreman/Clients and stop wasting time grinding off marks.

Products We Offer

Galvanizer’s Paint Marker: Standard size paint marker with a durable 3/16” nib. 12/box.

Galvanizer’s Paint Crayon: Makes wide, bold marks for instant identification. 12/box.

Galvanizer’s Paint Crayon: Makes wide, bold marks for instant identification. 12/box.

Summary of Features and Benefits

- Industry Uses: Metal fabrication, plating

- Suitable for all metal surfaces

- Marking range: -50 to 150ºF (-46 to 66ºC)

- Marks remove completely in pickling bath and won’t interfere with galvanizing

- Eliminates sanding or grinding to remove marks

- Allows for excellent adhesion during zinc coating

- Prior to pickling, marks are permanent. Won’t chip, peel, fade, or rub-off

- Writes on rough, rusty, oily, or wet surfaces

- Weather-resistant and fast-drying

- Fine or bold line marking options available

For expert advice on professional Marking Tools to get the job done right, call (514) 270-5377 or E-mail us at info@carmelindustries.com today.